ION EXCHANGE offers wide range of solutions for variety of cooling water problems

ION EXCHANGE offer a complete range of Fuel and Fire Side Additives –

ION EXCHANGE offers a complete range of coagulants and flocculants for solid liquid separation in variety of applications.

FILTERS –

REVERSE OSMOSIS PLANTS

ULTRAFILTRATION SYSTEM

DOSING SYSTEM

CLARIFIER

Complement your water treatment plants for optimum water management

ION Exchange (India) ltd. Offers a complete range of speciality, customised chemical treatment programmers to complement engineered water treatment and provide optimum plant performance.

Our highly trained engineers conduct in-depth surveys of your plant and system requriements, closely monitor the treatment programmers and regularly evaluate results to make requried adjustments for optimum benefit.

COOLING WATER TREATMENT

We offer a broad range of environmentally safe treatment programmers for open recirculating cooling water systems.

INDION corrosion and scale inhibitors control corrosion, scaling and fouling over a variety of water quality and system conditions. Our various biodegradable biocides control growth of algae, fungi & bacteria.

Closed Circuit Corrision & Scale Inhibitors

A complete range of INDION corrision inhibitors to control impingement & general corrision.

Once-through Circulation Systems

We offer non-polluting INDION chemicals that improve cooling efficiency systems.

Boiler Water Treatment

We offer a wide range of boiler water treatment programmers for low, medium and high preassure boilers to prevent deposits and corrison in pre-boiler boiler and post-boiler systems

Our unique DEHA based oxygen scavevgers offer superior protection against corrision even in condensate lines.

Complete condensate line treatment programmers solve specific corrison problems

Fireside Treatment

We offer energy-saving fuel additives that are vital for any combustion system treatment programme

Flocculants

Easytest Kits

Specially designed for on-the-spot analysis of make-up water, boiler water and cooling water, without a trained chemist.

Antiscalants & Memberance Cleaning chemicals

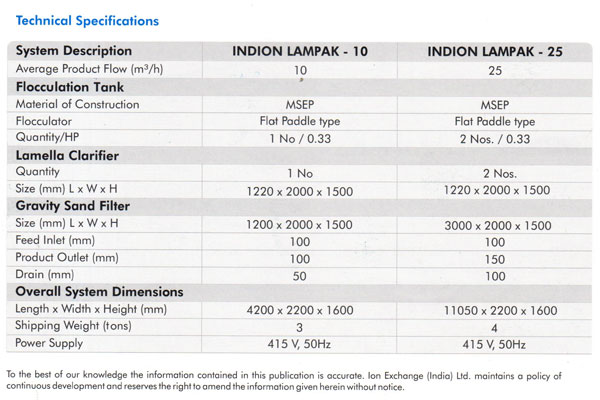

Water, is a precious natural resourse and clean drinking water is a basic necessity of life. A cute shortage and contamination of water in rural areas has always been a concern. At lon exchange we have developed INDION lampak which meets the community drinking water requriement.

INDION lampak is a compact unit consisting pump, static mixer, flocculator, lamella clarifier, gravity sand filter and chemical dosing systems. It produces disinfected drinking water with <5mg/I TSS from feed water containing 500mg/I of TSS . Best suited for community use, it can also be used for variety of industrial applications.

FEATURES

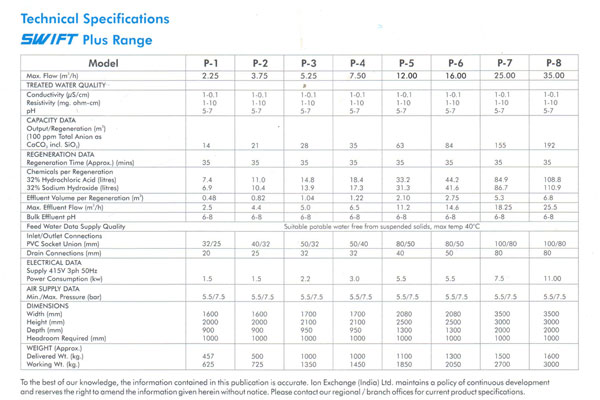

The latest INDION Swift range comprises a family of automatic twin-bed deionisers incorporating state-of-the-art counter-flow ion exchange technology previously available only in large, custom designed plants.

The operational cycle of these rapid generation, packaged units are controlled by volume throughput, which is pre-programmed in PLC according to the type of feed water. The ion exchange resins are never fully exhausted ensuring optimum deionised water production at all times.

Regeneration takes just 35 minutes- after a minimum service cycle of two hours- minimising the need of both, a stand by plant and the storage of large volimes of water. As regenarion of the cation and anion beds is simultaneous, the effluent streams are largely self-neutralising, reducing waste disposal costs and environment impact.

INDION Swift is exceptionally compact, and is skid-mounted on a corrosion-resistant frame which also accommodates a stainless steel multi-purpose pump.

In addition to optimising the performance of the plant during service and regenration, the pump provides a number of recirculation options to maintain high quality of water in the treated water tank.

INDION Swift plus features an additional cation exchange stage which is accomdated on the standard Swift skid. As a result, Swift plus produces mixed bed quality water having resitivity of greater than 1mg.ohm-cm for a minimum capital outlay. Running Cost is low because no additional regenerant chemicals are required and no extra effluent is produced.

Standard Features

Ion Exchange (India) Limited is India’s leading company in water and environment management, with a strong orldwide presence. Our superior applicatio knowledge and outstanding service support truely help provide customised, one – step solutions across diverse industries.

We offer range if INDFLOC Polymers for solid-liqude separation to varied industries . Solid- liquid separations is encountered in major industries such as chemicals, fertiliers, steel, paper and mineral processing. INDFLOC polymers are offered in varying range of molecular weight and ionicity to suit specific application. INDFLOC polymers can e profitaby used for:

COAGULANTS

These are synthetic cationic polymers based on:

Synthetic flocculants

These are polyacrylamides with medium to high molecular weight, which are water soluable and available in powder form in the following ionic types:

We also offer anionic emulsions for specific applications in water, waste water and process applications.

INDFLOC polymers are specially designed to improve the efficiency of solid-liquid sepaation in processes like:

Applications

Raw Water Treatment

Effluent Treatment

Colour Removal

In textile and tannery industry used for primary and secondary wase water treatment for high efficiency colour removal. Its proven advantages are low sludge generation in comparison with conventional treatment scheme and reduction in organic lead to downstream.

Deoiling

In refinery and steel mills it is used for breaking emulsified oil through coagulation and floatation by flocculaion aid. Specific polymer scheme for DAF (Dissolved Air Floatation) to achieve desired oil reduction in ooutlet clarified water.

Sludge Dewatering

Wide range of dewatering polymers to suite decanter, belt press, filter press appliacations for industrial, municipal and bio – sludge.

Pharmaceutical

Treatment in pharmaceutical broth and recovery of vaccines. Effluent treament coagulants polymers for decanter and screw pass operations.

Paper

Waste water treatment, fiber recovery, dissolved air floatation, deinking plant waste water solutions, sludge dewatering polymers for screw and blet press operaions for the paper industry.

Sugar

Sugar juice clarificatio aid and colour precipitant for sugar refining process and floatation aid.

Benefits

All Leading To

Dosing systems

The preparation of solution of INDFLOC speciality polymers plays a critical role in effective usage. We offer suitable dosing systems for specific applications which are easy to operate and maintain.

Advantages

Customer Support

Ion Exchange provides extensive training to help the customer in day-to-day moinitoring and maintaining plant efficiency. Our well trained extensive dealer network ensures prompt and personalised service.

Rechnical Service

INDFLOC treatment programme is backed by a well trained and experienced technical team which provides all the suport to improve he overall process efficiency of the plant.

The services includes

Industrial chemicls manufracturing unit at patancheru is ISO 9001, ISO 14001 and OHSAS 18001 certified

To the best of our knowledge the information in this publication is accurate. Ion exchange (India)Ltd., maintains a policy of continuous development and reserve the right to amend the information given herein without notice. Please contact our regional/ brand offices for current product specifications.

INDFLOC is a registered trademark of IonExchange (India) Limited.